The wing bend is a bending die changing the common sense of the sheet metal industry.

INTRODUCTION EFFECTS

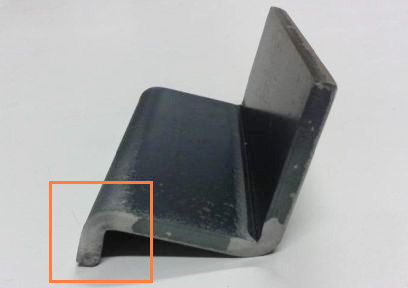

•Mark free bending

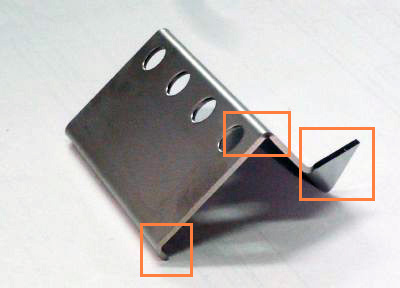

•Bending without the transformation near holes

•Hypotenuse bending without swelling

•Beautiful, wonderful short flange

•Wide range of processing work pieces thickness.

•Reduction the preparation substitute of the die.

•Correspondence to wide range bending angle as obtuse angle - right angle - acute angle.

•High precision bending.

•The die's expense is reduced.

•Workers can learn a sheet metal technology in a short time.

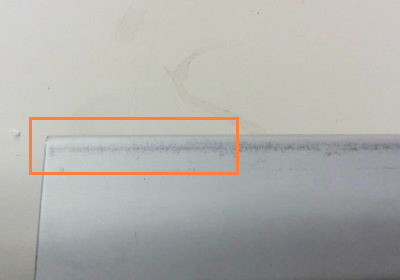

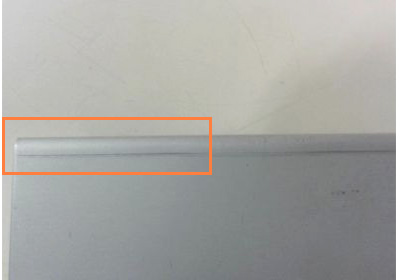

Mark Free Bending

wing bend(WB)

V Die

Bending without the transformation near holes/ Hypotenuse bending without swelling/ Beautiful, wonderful short flange

Range of processing work pieces thickness

Preparation substitute time for die

*WB:Following WING BEND abbreviated designation

The number of times of the preparation substitute

•V Die : Four times (two times of morning twice / afternoons) per day

[when there is little use frequency of one kind of V die]

•V Die: Two times (one time of morning once / afternoon) per day

[when there is much use frequency of one kind of V die]

•WB:After a preparation substitute of the beginning, I carry out only adjustment

| Preparation substitute time for die | ||

|---|---|---|

| V die | WB | |

| Disassembly / installation | 2min. | 3min. |

| Centering | 1min. | 1min. |

| Data input | 1min. | 1min. |

| Zero point seek | 1min. | 1min. |

| Trial bending adjustment | 3min. | 3min. |

| Preparation substitute time | 8min. | 9min. |

Process of the preparation substitute

•Disassembly / installation

•Centering (attaching Centering Jig)

•Data input

•Zero point seek

•Trial bending adjustment

Preparation substitute time per year.

[when there is little use frequency of one kind of V die]

•V Die = 8 minutes ×4 times×20 days ×12months /60 minutes = 128 hours

•WB = (9minutes + (3 minutes×4 time ×20 days ×12 months)) /60 minutes ≒ 48 hours

[When there is much use frequency of one kind of V die]

•V Die = 8 minutes ×2 times ×20 days × 12 months /60 minutes = 64 hours

•WB=(9 minutes +(3 minutes × 2 times × 20 days ×12 months)) /60 minutes

=24 hours

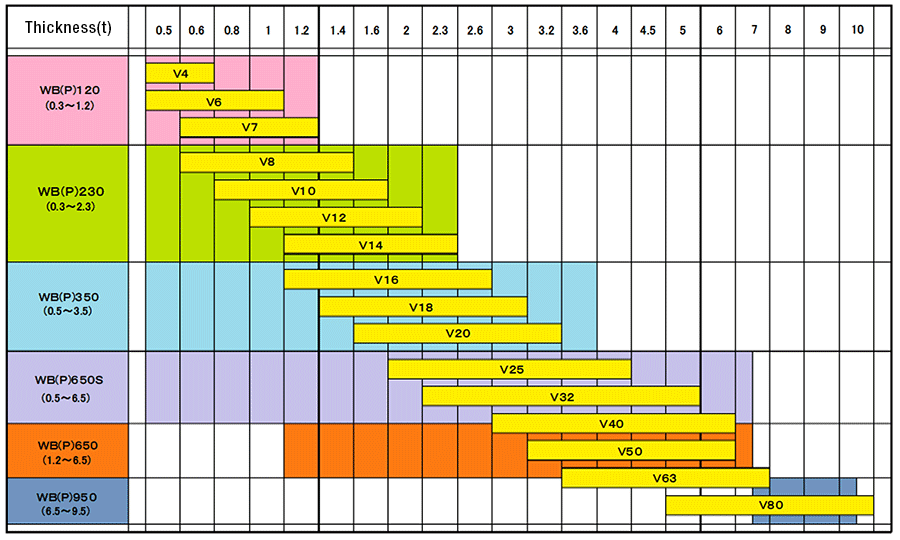

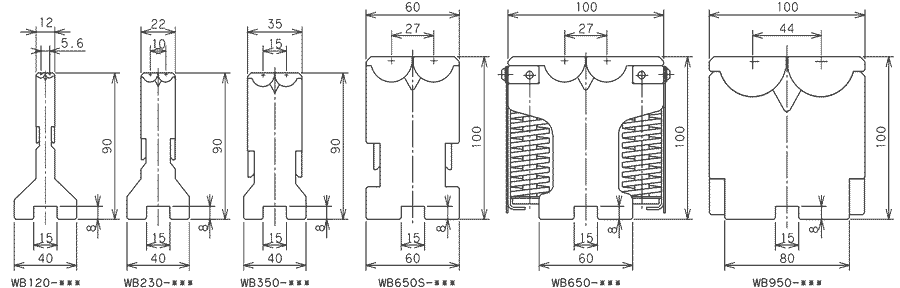

PRODUCTS LINE UP

STANDARD TYPE

*You can flick charts.

| Model No. | WB120-*** | WB230-*** | WB350-*** | WB650S-*** | WB650-*** | WB950-*** |

| Work piece thickness | 0.3~1.2mm | 0.3~2.3mm | 0.5~3.5mm | 0.5~6.5mm | 1.2~6.5mm | 6.5~9.5mm |

| Die height | 90mm | 90mm | 90mm | 100mm | 100mm | 100mm |

| Die length | 50/100/ 200mm |

50/100/ 200mm |

50/100/ 200mm |

50/100/ 200mm |

50/100/ 200mm |

100/200mm |

| Resistance pressure | 500kN | 700kN | 1000kN | 1500kN | 1500kN | 2000kN |

*1.Model No. " *** " represent the die length.

*2.We have Type C which can correspond for TRUMPF Press Brake with fitting the FIT BAR to standard type.

*3.WB120 and 230 have separated type (90 set:Die length 15/20/25/30mm)

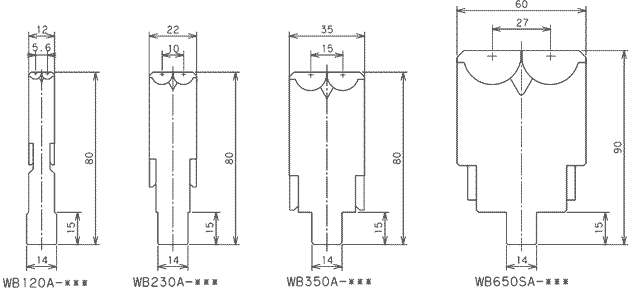

A Type ~AMADA 1V HOLDER

*You can flick charts.

| Model No. | WB120A-*** | WB230A-*** | WB350A-*** | WB650AS-*** |

| Work piece thickness | 0.3~1.2mm | 0.3~2.3mm | 0.5~3.5mm | 0.5~6.5mm |

| Die height | 90mm | 90mm | 90mm | 100mm |

| Die length | 50/100/ 200/500mm |

50/100/ 200/500mm |

50/100/ 200/500mm |

50/100/ 200/500mm |

| Resistance pressure | 500kN | 700kN | 1000kN | 1500kN |

*1.Model No. " *** " represent the die length.

*2.WB120A and 230A have separated type (90set:Die length15/20/25/30mm)

ACCESSORY / ADAPTER

Rail & Plate

Centering Jig

OPERATION PRINCIPLE

SPECIFICATION / SELECTION LIST

*The details download PDF than the following [specifications / choice list], and, please refer.

SOLUTION EXAMPLE

Mark free, Reduction of substitute time and Near hole bending, we can solve various problems of V Dies.

SOLUTION EXAMPLE OF WING BEND SERIES

FAQ

We reply about usable or not for each press brake machine and sales advisability of parts.

FAQ OF WING BEND SERIES

![wing bendシリーズ[Ultimate•High performance bending Die]](images/title04.gif)